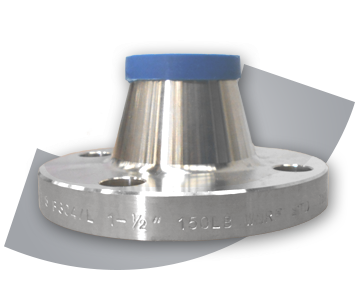

Forged Flanges

ASTM A182 Stainless steel forged flanges. These are detachable components that are used along with gaskets or seals to assure the correct adhesion. Its round design includes some holes in order to be affixed with studs and bolts.

Learn More About our Stainless Steel Forged Flanges

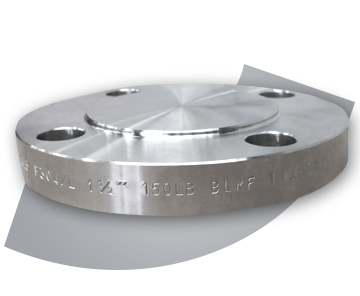

Blind

The blind flanges have the function as covering device or closing end for pipes.

They are manufactured under the dimensional specifications of ASME B16.5 standard and the manufacture according to ASTM A182/ ASME SA182 standards, included within the commercial devices line of WILSON STAINLESS.

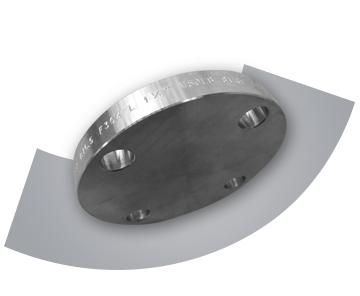

Threaded

Thread Raised Face flanges are used for special circumstances with thir main advantages being that they can be attached to the pipe without welding.

Today are used almost exclusively in smaller pipe sizes. They are manufactured to the dimensional specifications of ASME B16.5 standard and ASTM A182 for manufacturing standard, within the WILSON STAINLESS commercial devices line. They are made of stainless steel and special alloys by forging process.

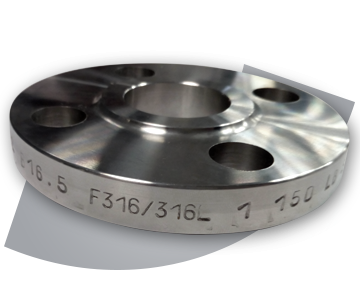

Slip On

The connection with the pipe is done with two fillet welds, as well at the outside as also at inside of the flange.

The calculated strength from a Slip On Flange under internal pressure is of the order of two-thirds that of Welding Neck flanges, and their life under fatigue is about one-third tat of the latter. The Slip-On Flanges are manufactured under the dimensional specifications of ASME B16.5 standard and the manufacture standards ASTM A182/ASME SA182, within the commercial devices line of WILSON STAINLESS. They are made of stainless steel and special alloys by forging process.

Lap Joint

A pipe is welded to the stub end and the lap join flange is free to rotate around the stub end,

the benefit of this is to get facility for easier dismantling of piping. They are manufactured under the dimensional specifications of ASME B16.5 standard and ASTM A182/ASME SA182 manufacture standards, within the commercial devices line of WILSON STAINLESS. They are made of stainless steel and special alloys by forging process.

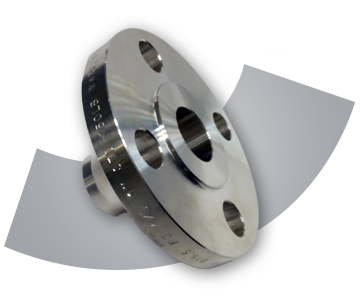

Welding Neck

The Welding neck flanges are easy to recognize at the long tapered hub,

this provides an important reinforcement for use in several applications involving high pressure, sub-zero and elevated temperatures. These are manufactured under the dimensional specifications of ASME B16.5 standard and the manufacture ASTM A182/ASME SA182 standards, within the commercial devices line of WILSON STAINLESS. They are made of stainless steel and special alloys by forging process.

Socket Weld

The Socket Weld flanges initially developed for use on small size high pressure piping.

Their static strength is equal to Slip On Flanges, but their fatigue strength is 50% greater than double welded Slip On Flanges. The connection with the pipe is done with one fillet weld, at the outside of the flange. But before welding, a space must be created between flange and pipe (a gap of 1.6 mm). Socket Weld flanges are manufactured under the dimensional specifications of ASME B16.5 standard and the manufacture standards ASTM A182/ASME SA, within the commercial devices line of WILSON STAINLESS. They are made of stainless steel and special alloys by forging process.

Other Products

solutions

Contact Us